Small Powder Coating Ovens are compact, efficient systems designed to cure powder-coated surfaces for workshops, startups, and DIY enthusiasts. These ovens deliver precise temperature control (typically 300°F–450°F) to melt and bond powder particles into durable, eco-friendly finishes. Built with space-saving designs, they often feature electric heating elements, insulated chambers, and user-friendly controls. Ideal for small-scale projects like automotive parts, furniture, or tools, these ovens balance affordability with professional-grade results. Their portability and low energy consumption make them perfect for garages, small factories, or hobbyists seeking high-quality coatings without industrial-scale investments.

1. Small Powder Coating Oven Components and Structure

A Small Powder Coating Oven consists of a compact insulated chamber, electric heating coils or infrared panels, temperature sensors, and a digital controller. The chamber, lined with heat-resistant materials like ceramic fiber, retains heat efficiently. Convection fans ensure even airflow to prevent uneven curing. Safety features include automatic shutoff, overheat alarms, and ventilation systems. Benchtop models often have lightweight frames, while larger compact units may include adjustable racks for multi-layer curing.

2. Applications of Small Powder Coating Ovens

These Small Powder Coating Ovens are ideal for small-batch production or custom projects. Automotive repair shops cure coatings on brake calipers, rims, or engine parts. DIY enthusiasts coat bicycle frames, tools, or outdoor furniture. Jewelers and artists use them for metal sculptures, while small manufacturers treat electronic enclosures or appliance components. Their versatility also extends to prototyping, custom signage, and restoring vintage items.

3. Design Considerations for Small Powder Coating Ovens

Key design factors include space efficiency, temperature uniformity, and safety. Insulation quality impacts energy efficiency and operational costs. Ensure the oven’s internal dimensions accommodate typical project sizes. Opt for models with programmable timers and precise thermostats to avoid under-/over-curing. Ventilation systems must manage fumes, especially in enclosed spaces. Compliance with safety standards (e.g., UL or CE) is critical for fire prevention.

4. How to Choose the Right Small Powder Coating Oven

Consider workspace size, budget, and project requirements. Benchtop ovens suit limited spaces, while freestanding units offer higher capacity. Electric models are quieter and safer for indoor use, whereas gas-powered options heat faster. Check temperature range compatibility with your powder type. Prioritize ovens with energy-saving modes and easy-to-clean interiors. Read reviews for reliability and verify warranty terms.

5. Q&A on Small Powder Coating Oven Devices

Q: What temperature range works for most small ovens?

A: Most powders cure between 300°F–450°F, but always verify your powder coating temperature specifications.

Q: Can small ovens handle thick metal parts?

A: Yes, but ensure the oven’s thermal insulation retains heat long enough for thorough curing.

Q: Are these ovens energy-efficient?

A: Electric models with ceramic insulation reduce energy consumption, lowering long-term costs.

Q: How to maintain a small powder coating oven?

A: Clean residue regularly, inspect heating elements, and calibrate temperature controls annually.

Q: What safety features are essential?

A: Look for automatic shutoff, ventilation systems, and safety certifications like CE or UL.

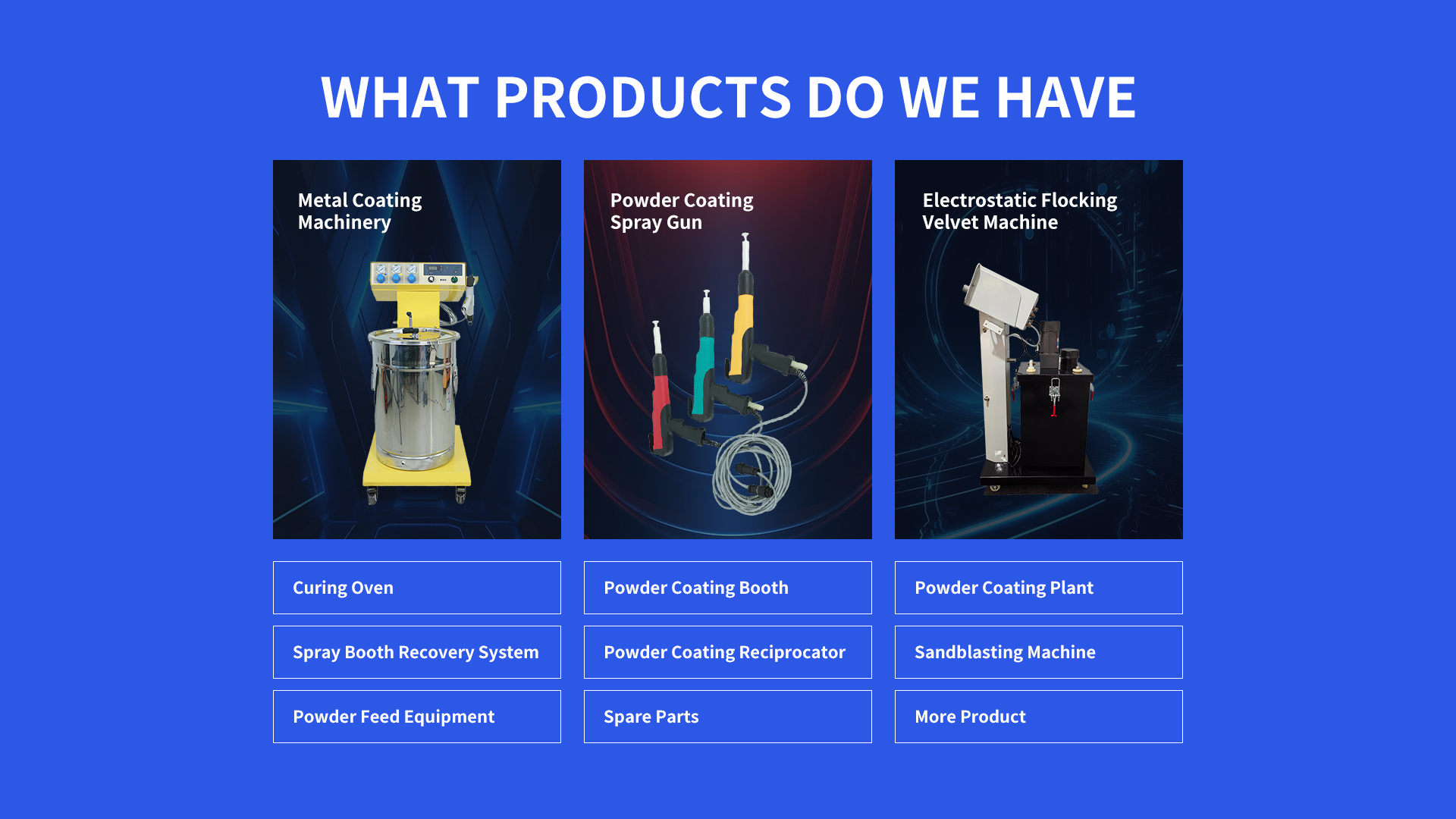

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com